|

|

03-09-2022, 11:20 AM

03-09-2022, 11:20 AM

|

#21

|

|

Senior Member

Name: Donald

Trailer: Happier Camper HC1 (Subaru Outback Stranded Me)now towing with RAM 1500 Ecodiesel Major overkill.

California

Posts: 125

|

Love my Lithium Conversion

I am not sure about your fridge and a lithium battery, but just changed over my trailer to a Lithium 100 ah vs. a 100 ah AGM. (with built in heating) Basically almost doubled my useable amp hour capacity. I was caught by surprise that I needed to upgrade the converter section of my 6 year old Progressive Dynamics panel, but now have a switch that will set it to Lithium charge characteristics. My chest fridge runs on 12 volts from a smaller, DIY, LiFePo power station and resides in the cab of the truck. A truck mounted solar panel feeds the power station for the fridge. I am really liking this setup. Set it and forget it.

__________________

Don

Sacramento, California

|

|

|

03-09-2022, 11:37 AM

03-09-2022, 11:37 AM

|

#22

|

|

Senior Member

Name: Rod

Trailer: 2014 GWV Trillium Sidekick 1500

British Columbia

Posts: 195

|

With lithium it is not the demand side you need to worry about but the charging side. To charge lithium you need a proper lithium aware charger that has the proper charge algorithms or else a Battery Management System on the lithium battery that compensates for lead acid charge algorithms. The lithium battery will want to charge at a high amperage rating and this can damage your vehicle alternator, so you will want to either disconnect the fuse for the aux power wire in your 7 way wiring on the vehicle side or get a DC to DC charger that will limit the amount of amps that it draws on the vehicle side installed as well. You can check out some videos made by Victron Energy on this subject. I completed a full lithium battery conversion on my Trillium last summer, it was a little pricey but it easily doubled if not tripled my battery capacity from what I had with the existing lead acid footprint (80ah battery). The battery charged much better with solar using the existing roof panel and a lithium aware solar charge controller. I installed a Victron Smart Solar charge controller, Victron battery monitor, Victron DC to DC converter, and lifepo4 lithium battery with a BMS that has Bluetooth connectivity for monitoring it as well and I can tell you that when the lithium battery is very low it will demand up to a 60AMP charge. For my truck this is fine because it has a Heavy Duty 140 AMP alternator in it (GMC 3500HD) and 10 gauge wiring to the hitch plug, and then 10 gauge wiring in the trailer plug to DC to DC converter, but for a regular vehicle I could definitely see the 60AMP additional demand stressing the alternator or melting the aux power wire for the hitch plug or the trailer plug.

|

|

|

03-09-2022, 11:37 AM

03-09-2022, 11:37 AM

|

#23

|

|

Senior Member

Name: Tony

Trailer: Boler

BC

Posts: 198

|

Quote:

Originally Posted by EllPea in CA

My RV guy worries about adding a lithium battery to a 30 y/o trailer... mainly the refrigerator. He says the battery output is different to what the refrigerator normally gets?

I have no converter or other legacy stuff in there, so if I do lithium I'm kind of starting from scratch anyway, but I don't want to push the refer over the edge.

Any discussion on this issue appreciated, TIA! |

Most batteries that advertise themselves as 12V have been constructed in such a way as to mimic 12V Lead Acid batteries. As long as you buy a battery that has a built in Battery Management System, your trailer will not know the difference.

In practice note that the specifications for most Lithium batteries say good for 1,000 cycles, or some other number, what they are counting is the charging, the battery will last much longer if you do not charge it until it is at 20% and only charge it to 90%, tho most BMS's will only charge the cells to 90% or 95% anyway.

Unlike LA which likes you to store the batt fully charged Lithium batts store better if kept cool and are stored at 50% charged.

If you go to ebike sites you will find more information than you could imagine, many build their own batteries and have been using LI batts for years.

__________________

We're lost but we're making good time.

|

|

|

03-09-2022, 12:58 PM

03-09-2022, 12:58 PM

|

#24

|

|

Senior Member

Name: Ellpea

Trailer: 1989 Lil Bigfoot

CA

Posts: 1,382

|

Quote:

Originally Posted by Rodre

...The lithium battery will want to charge at a high amperage rating and this can damage your vehicle alternator, so you will want to either disconnect the fuse for the aux power wire in your 7 way wiring on the vehicle side or get a DC to DC charger that will limit the amount of amps that it draws on the vehicle side installed as well.

|

Rodre, is this a concern when the vehicle is in motion? Or only when the motor is off but the 7-pin is still connected?

And are you recommending a DC to DC charger on both sides of the battery?

Quote:

|

...I installed a Victron Smart Solar charge controller, Victron battery monitor, Victron DC to DC converter, and lifepo4 lithium battery with a BMS that has Bluetooth connectivity for monitoring it as well and I can tell you that when the lithium battery is very low it will demand up to a 60AMP charge. For my truck this is fine because it has a Heavy Duty 140 AMP alternator in it (GMC 3500HD) and 10 gauge wiring to the hitch plug, and then 10 gauge wiring in the trailer plug to DC to DC converter, but for a regular vehicle I could definitely see the 60AMP additional demand stressing the alternator or melting the aux power wire for the hitch plug or the trailer plug.

|

OK, I just had the 7-pin and hitch installed. Am contacting installer to query about wire gauge. He will also be able to tell me about amperage on the alternator. Thanks for the heads up on this!

__________________

Best,

EllPea in CA

|

|

|

03-09-2022, 01:28 PM

03-09-2022, 01:28 PM

|

#25

|

|

Senior Member

Name: John

Trailer: Roamer 1

Smith Valley, Nevada

Posts: 2,892

|

Quote:

Originally Posted by Rodre

With lithium it is not the demand side you need to worry about but the charging side. To charge lithium you need a proper lithium aware charger that has the proper charge algorithms or else a Battery Management System on the lithium battery that compensates for lead acid charge algorithms. The lithium battery will want to charge at a high amperage rating and this can damage your vehicle alternator, so you will want to either disconnect the fuse for the aux power wire in your 7 way wiring on the vehicle side or get a DC to DC charger that will limit the amount of amps that it draws on the vehicle side installed as well. You can check out some videos made by Victron Energy on this subject. I completed a full lithium battery conversion on my Trillium last summer, it was a little pricey but it easily doubled if not tripled my battery capacity from what I had with the existing lead acid footprint (80ah battery). The battery charged much better with solar using the existing roof panel and a lithium aware solar charge controller. I installed a Victron Smart Solar charge controller, Victron battery monitor, Victron DC to DC converter, and lifepo4 lithium battery with a BMS that has Bluetooth connectivity for monitoring it as well and I can tell you that when the lithium battery is very low it will demand up to a 60AMP charge. For my truck this is fine because it has a Heavy Duty 140 AMP alternator in it (GMC 3500HD) and 10 gauge wiring to the hitch plug, and then 10 gauge wiring in the trailer plug to DC to DC converter, but for a regular vehicle I could definitely see the 60AMP additional demand stressing the alternator or melting the aux power wire for the hitch plug or the trailer plug. |

Stating that a lithium battery will damage the alternator and can be avoided by disconnecting the seven pin wiring is incorrect. Typical seven pin wiring is 12 gauge, or less, and not robust enough to burn out an alternator. The story about alternators being burned out is based on false or misleading advertising by Victron. Please don't repost suspect information like that as useful fact. Appropriate size wiring is always required for a given load and alternators in a test lab, run in ways that are not within normal operating perameters, just to make an advertising point, should not be used as evidence of a real problem. In that video, which seems to have been taken down, Victron used a very small alternator, ran it below vehicle idling speed, had no normal cooling fan cooling it, had a very large and dead lithium battery connected directly to it, and had very large and short conductors that could not limit the load. In vehicles that charge trailer batteries, there is a starting batter in the circuit and very long conductors to the lithium battery. It was not real world use and was dishonest. Further, I've never seen a seven pin harness capable of carrying 60 amps continuous and able to burn out even a small alternator. I have 480 AH of lithium and have repeatedly charged that bank with a direct connection to the tow batteries with no problem. My alternator is plenty big enough, but based on your theory, it should have burned up my wiring. Never a problem.

__________________

I only exaggerate enough to compensate for being taken with a grain of salt.

|

|

|

03-09-2022, 01:51 PM

03-09-2022, 01:51 PM

|

#26

|

|

Senior Member

Name: Rod

Trailer: 2014 GWV Trillium Sidekick 1500

British Columbia

Posts: 195

|

This is the video I speak of, I am only posting it for people to draw their own conclusions, not to get into any arguments:

https://youtu.be/jgoIocPgOug

I don't think the lithium battery would be able to get 60 amps from the alternator due to the 12 gauge or smaller wiring but I do think it would cause the aux wire to get hot and possibly cause the insulation to melt. If you have your trailer plug aux going directly to the tow vehicle battery you would be reducing the resistance so this might be helping it not have issues.

In my setup I have the DC to DC charger mounted in the RV and have the trailer plug aux wire going directly into its positive input side and the negative grounded to the trailer frame. Then I have the output side of the DC to DC converter going to the RV power center DC input. All I know is that I have it set to charge at 25AMP and the wires no longer get hot. All my wiring for this setup is 10 gauge and rated for about 40 amps end to end with the total distance of wiring used. I am also using a 30AMP fuse in the tow vehicles aux power cable fuse bay.

If there is any concern with this it would only be when the vehicle is started and the alternator is running. A lead acid battery normally won't output 60 amps of continuous power long enough for things to get hot.

|

|

|

03-09-2022, 01:52 PM

03-09-2022, 01:52 PM

|

#27

|

|

Senior Member

Name: Tony

Trailer: Boler

BC

Posts: 198

|

Quote:

Originally Posted by Rodre

With lithium it is not the demand side you need to worry about but the charging side. To charge lithium you need a proper lithium aware charger that has the proper charge algorithms or else a Battery Management System on the lithium battery that compensates for lead acid charge algorithms. The lithium battery will want to charge at a high amperage rating and this can damage your vehicle alternator, so you will want to either disconnect the fuse for the aux power wire in your 7 way wiring on the vehicle side or get a DC to DC charger that will limit the amount of amps that it draws on the vehicle side installed as well. You can check out some videos made by Victron Energy on this subject. I completed a full lithium battery conversion on my Trillium last summer, it was a little pricey but it easily doubled if not tripled my battery capacity from what I had with the existing lead acid footprint (80ah battery). The battery charged much better with solar using the existing roof panel and a lithium aware solar charge controller. I installed a Victron Smart Solar charge controller, Victron battery monitor, Victron DC to DC converter, and lifepo4 lithium battery with a BMS that has Bluetooth connectivity for monitoring it as well and I can tell you that when the lithium battery is very low it will demand up to a 60AMP charge. For my truck this is fine because it has a Heavy Duty 140 AMP alternator in it (GMC 3500HD) and 10 gauge wiring to the hitch plug, and then 10 gauge wiring in the trailer plug to DC to DC converter, but for a regular vehicle I could definitely see the 60AMP additional demand stressing the alternator or melting the aux power wire for the hitch plug or the trailer plug. |

Too many urban myths about li batteries, Your alternator will happily charge at full tilt, but you need to know the maximum charge rate for the battery, if the battery management system and the cells can handle 100 amps then your are good to go up to 100 amps. The charge rate is usually expressed as C plus a numeral. Every decent li batt will have thermal protection, built in to the BMS. If the charge rate is too high for the cells they will heat up and the thermister will shut down the charging, if it is too cold for the battery to accept a charge (remember charging is a chemical reaction) then the thermister will not allow the battery to charge.

I built the li batt for my electric garden tractor, & charge it with what ever is handy, I am building an Li batt for my freighter trike and it will be a smaller version of the tractor batt. Again I may use solar, a 36V LA charger which tops out at 41.2 volts which is 95% on my batt, on the tractor I have a variable voltage power supply set for a max of 40.5 volts or 90%. all good for a nominal 36V system.

As mentioned earlier go to e bike sites such as Endless Sphere, or Ebike.com

There is a wealth of information posted by knowledgeable people. On those sites mis information gets jumped on very quickly. Here lots of RVers get their info from the guy next door who got it from a cousin who works at...

__________________

We're lost but we're making good time.

|

|

|

03-09-2022, 03:04 PM

03-09-2022, 03:04 PM

|

#28

|

|

Senior Member

Name: Rod

Trailer: 2014 GWV Trillium Sidekick 1500

British Columbia

Posts: 195

|

Yes, definitely do your own research. To condense what I was trying to say:

If you install a lithium battery in your trailer and the trailer aux power line fuse keeps blowing in the tow vehicle AND you want to be able to safely charge the lithium battery while towing (ie: do not put in a higher amp fuse in the tow vehicle) you may want to consider getting a DC to DC converter between your trailer and tow vehicle. Renogy makes a 20 amp one that is probably around $80 or $100 that will do the job safely as I believe most modern vehicle alternators and trailer aux wiring should be able to do an extra 20 amps. If in doubt check your vehicles manual for the fuse amperage for the aux trailer power and go 5 amps below when selecting a DC to DC charge controller. If the DC to DC is configurable then set the max amperage on the input side to be 5 amps below the fuse rating. On the output side make sure you have the correct wire gauge for the amperage and distance to your battery or power converter. This is free advice so please do your own research and adapt to your environment and use case scenario :-)

__________________

~Rodre

I am a Trilliumaire - I can go camping anytime, any place, anywhere.

|

|

|

03-09-2022, 04:00 PM

03-09-2022, 04:00 PM

|

#29

|

|

Senior Member

Name: John

Trailer: Roamer 1

Smith Valley, Nevada

Posts: 2,892

|

Rodre,

The video you linked is not the original Victron video that made the burnout claim, and it seems to have been taken down, but your video came to the same conclusion. That is, at 1500 RPM. And they stated that 1500 RPM was above engine idling speed. That is true for the engine, but not the alternator. In vehicles, alternators are belted to the crankshaft with a three or four to one ratio. Engines typically idle at about 750-800 RPM. So, the minimum speed a typical alternator would be running at would be approximately 2,250 RPM - 3,200 RPM. And alternators are typically, or always, mounted behind the engine fan. The test shown had no extra fan blowing on the alternator. These and other problems with the video do not represent what happens in the real world with charging systems and should not be used to demonstrate that alternators will burn out if used to charge lithium batteries. There's more to the story, such as alternator rated output, wire size and wire length.

__________________

I only exaggerate enough to compensate for being taken with a grain of salt.

|

|

|

03-09-2022, 04:14 PM

03-09-2022, 04:14 PM

|

#30

|

|

Senior Member

Name: Ray

Trailer: scamp

Indiana

Posts: 849

|

Quote:

Originally Posted by EllPea in CA

My RV guy worries about adding a lithium battery to a 30 y/o trailer... mainly the refrigerator. He says the battery output is different to what the refrigerator normally gets?

I have no converter or other legacy stuff in there, so if I do lithium I'm kind of starting from scratch anyway, but I don't want to push the refer over the edge.

Any discussion on this issue appreciated, TIA! |

Weird. Don't know if he is confused or if he did not communicate well. There should be absolutely no problem with the output from a Lithium battery. The fact that you say that he mentioned the frig would indicate to me he is confused. A lithium should be putting out the same voltage and amps as a lead acid. So for using the power from one there really is no difference.

Now as mentioned here the charging is kind of a different thing. When it comes right down to it, a lead acid really can take whatever reasonable charge you send at it. If the charge voltage is within range it will protect itself and make sure it is not charge too fast. And again within reason it will not over charge. Now most systems think 14 - 14.4 volts is a good charge voltage is a good charge voltage. And that will shorten the life of the battery a bit. The ideal is 13.8 volts. But all of this will not cause major problems as long as it is reasonable. BUT lithium are different.

It is possible to both charge a lithium too fast and too much. Especially too fast. A lead acid really only has a charge voltage spec. And as long as you are within spec you are good regardless of the status of the battery. Now a lead acid will give out voltage and over time that will drop as it becomes discharged. A lithium will do the same thing with a different discharge curve, but really the same thing. Both can end up will below the desired 12 volts. But then when it comes to charging things become vastly different.

When you are ready to charge your lead acid battery you just hook it up to voltage within the charge spec. Even it it is say at 8 volts it will charge a bit faster than at say 11.5 volts. As the battery charges; some, hopefully most, of the energy is put into the battery as a charge that can then be drawn out. But some turned into heat by what is called internal resistance. With a lead acid battery this internal resistance and other factors make sure that your battery doesn't get damages and nothing bad happens because of the heat. Now if there is an internal short the battery can crack and lead acid. But that is about as bad as it gets. Some times in rare cases there can be a hydrogen explosion, but those even are close to impossible with a modern battery. That is why we use battery boxes by the way so a failure can be easy to deal with. BUT note I said lead acid. This is also true of most other types of batteries. But it is not true of a modern lithium (or phosphate) battery.

A lithium battery will accept a charge at a rate that heats it up and messes it up. A lithium battery will have both a charge voltage spec, BUT also a charge rate spec. Now with a lead accident you in a lot of cases don't really need a "charger". All you need is a supply of voltage what matches the spec. If the battery calls for say 13-14 volts then the power supply can put out 14 volts and the battery will take it in. IN most cases the power supply system such as a "battery charger" will quickly get to its maximum rate and drop the voltage, but that is to protect the wiring and the unit. It is not to do anything for the battery. In fact you probably have experienced this. If you have been running on battery and drain it and then hook up to shore power and let the converter run the camper and charge the battery you will notice that at the start the power to everything is a bit lacking. The lights will be a bit dim and the stove spark may not work. But then in a few minutes all is good and you wonder if you were experiencing this or not. What happened is that the battery was taking enough current from the converter that it dropped in voltage so that to much current for the wiring and for it would not be generated.

If you were to hook up a charger capable of say 200 amps dc of the proper voltage to the battery it would be perfectly fine. Its internal resistance will drop the amps to match the batteries ability to shed heat. Now there can be a problem if there is a short, but then all that happens is that the battery cracks and then stops taking any current. And when that happens the battery was already toast anyway. A healthy lead acid battery would be quite happy hooked up to this device. In fact we do that regularly. Remember those booster chargers that allow you to start a car with a dead battery without first charging it up. That is exactly how they work.

But as I said lithium is different. It is possible to charge a lithium to fast. And if you do you can get a much more "spectacular" result than with a lead acid failure. You can get a fire or even an explosion. But only if they are charged wrong. Do things right and you are good. You would not even need the battery box because the cracking and leaking because the battery went bad is not possible. But a healthy lithium can be charged to fast and go into failure. Now if you were to say hook that 200 a,p power supply up to about any lithium battery designed for 12 volt deep cycle use and you will get a very bad result. You probably would not want to be any where near it. There are even a couple of youtube videos by the "lets film stuff really blowing up or burning spectacularly" channels. But again that is if you are charging it improperly.

Remember that comment I made about the lithium (and phosphate) batteries having a charge rate spec. That is the issue. It is possible to charge a lithium battery to fast and put it in failure. Even if it is not spectacular it will be dead and they are expensive. And most of their warranties don't cover this. So dropping a "12 volt" lithium battery into a camper and using it to power the camper should be fine. But if you then charged it the same way that a lead acid battery is charged you will be very unhappy. And you can charge them one of three ways. This is kind of hinted at above, but lets talk about this directly. First obviously you can just hook a battery charger up across it. That is the most obvious one. Everyone can probably understand this. The second way it that you can hook up shore power. Normally the way the converter that is the 12 volt part of shore power is wired is that the battery is just in parallel with the main. That is why when you first plug it in the voltage drops for the camper and then comes back up as the battery is charged. Then the third way is that the TV can be hooked up and probably the engine running a the alternator running and producing power. Again this is normally hooked up in parallel with the camper wiring and that battery (and the converter). The voltage will drop while the battery is charging. Now most of the time the wiring going to the rv7 connector and the distance will produce enough drop not to allow the battery to be over charged. But you would never want to count on this. In each case basically the voltage produced is either like 13-14 volts or the maximum the source can put out without regards to the needs and requirements of the battery. That as we have said is fine for a lead acid battery for which this system is designed. But it would be disastrous for a lithium or similar battery.

The prevention of a over charge is where a lithium battery charger comes in. These are in a way true battery chargers and not just a dumb power supply used to charge the battery like we see with a lead acid battery. They are actually "smart" mostly they actually have a small computer of some kind in them. That small computer knows all about lithium and other batteries. And it prevents over charging. They are also smart enough to detect a damaged battery and will not allow any charging, so they will not allow a damaged battery to do damage. They will drop the voltage in order to prevent the battery from getting charged to fast and failing. Now strange as this sounds they will frequently at the start of the charge limit the voltage to well below the level of being charged. If you have discharged a lithium battery to say 8 volts (you should not really do ths, but it happens) then the charger will prevent more than say 10.5 volts from being sent to the battery and then up that voltage to maintain the rate till it is fully charged. And as I said if the battery is bad the charger will goto 0 volts and put out an indicator of why. By the way some bad lead acid batteries can be resurrected by hooking them up to a lithium charger. Actually a lithium charger will handle a properly sized lead acid battery with no problems. So if you are not already trying to make the change, but are thinking of in the future and you are replacing your converter (more on those below) you can actually get a lithium one and use it on your lead acid until you make the switch.

Now how to get a lithium charger in this case is the question. Now for a battery charger that is easy. Get a battery charger which is rated for lithium. The only catch here is that current rate spec that does not exist for lead acid batteries. And that rate is important and is different for different batteries. So you will either need to get a charger that is rated for the current spec of the battery or which can be adjusted for that rate. And then remember to adjust it. That is the easy side. The RV converter is another side.

Now back to the original question. The author specified that the camper had no converter. I would certainly question that and double check it. But I guess that is possible. Might be a great time to add one as you can add one that supports lithium batteries as your charger. Now a seperate question is what happens to power from the TV is it routed into the camper wiring or is it disconnected? Important questions. And that will change how you handle this. I am going to assume that you have both as that way I can explain the process with all of them if you don't have one you will just skip the steps involving them.

The first thing to do is to get a converter that will support your lithium battery. You will need one with the smart charging functionality of a lithium battery charger. Now as I covered above most converters are kind of dumb and are simply hooked up to the battery, the HV and camper DC wiring in parallel. When the converter has power it just puts out power to its maximum rating. As a 35 amp convert will put out 13.8-14 volts up to the limit of its 35 amp capacity. Then it will drop the voltage as needed to not put out any more than that. But remember that will like pretty much insure you lithium battery is killed. The first thing you will notice about the new converter (other than it is much more expensive ;-) Is that it has multiple places to attach wiring. A normal converter generally has a single set of connection points. Generally a red (hot) and black (ground). Then some times an actual ground connection. It is pretty easy to wire this in. Just connect it up to the camper wiring and it is connected to everything it needs to be connected to. And that almost always is the way that camper wiring comes today. So only that style of converter will be "plug and play" that is turn off the power, disconnect the wires. Remove the old unit and install the new one. Then hook up the same wires to the same type of places and turn on the power. Sorry it will not be that simple to do the news setup.

There will be several steps and some rewiring needed to install the new lithium supporting converter. Always good to take a bunch of pictures of what you have now and label it. But now the first steps will be the same. Pull all of the power. Remember to disconnect the battery. ;-) Remove the wiring for the old unit and uninstall it. Now the new steps. First figure out exactly where to install the new unit. Probably where the old one is but in some cases you will need to move it, or more likely reorient it. Now set the current levels for the charge. After all that is why we are here right. Now some of these new fanciest converters will actually allow you to hook up and charge two separate lithium batteries. Of course that is more expensive. In some cases you can hook up batteries in parallel and up the charge rate. Get lots of advice from an expert before doing this. Now install the unit.

Time for the wiring. Now you will need to get power to it, and this generally will be the exact same way as the old one. And then you will hook up the trailer wiring to the place on the converter that is labeled for that. Now the new part. First the battery. Remember that the old battery is just hooked up in parallel with the trailer wiring in some manner. Some times this is at the converter. A few converters for lead acid have a separate battery connection and wiring to the battery box. That will almost never be how they leave the factory. But mine actually has that. In that case hook that up to the battery connection. But usually you will have to run new wiring for this. I use heavy duty drop cord wiring for this. Now some times you can buy this cheapest without ends as a place like Lowes. But generally it is cheaper to just buy a drop cord. And remember you will need to pieces here. But one way or other you will need to wire the battery box separately to the converter on the labeled ports.

Now we have that Tow Vehicle (TV). It also is most likely wired into the existing system in parallel with the camper wiring. In most cases the converter is at the back or middle of the camper and the TV therefore its wiring at the front. So usually the connection for the TV is wired into the camper wiring at the front of the camper. So you will need to find this point. Then you need to disconnect it and run the wiring for the TV power to the converter. This is where an expert may be needed. Remember the ground line for the RV 7 not only is ground for the supplied power, it also is the ground for the signal and tail lights. So you will have to plan on exactly how the ground is handled. And part of that is making sure that any route to the lighting is able to handle that current and also the current of the inside DC wiring. But regardless the RV hot needs to be connected to the right place on the new converter.

Now in a few cases there are actually also boxes which go between the camper wiring and the battery that takes care of all of this. But for the pricing if you can update the wiring to allow for a modern converter that will work better.

Now one other warning. Mostly when we replace the converter we also up its capacity. Going say form a 20 amp to a 40 amp. There are a lot of wiring issues on this other than the battery change, but mostly we want to do this. But that then ups the amount of heat the converter generates. So we need to make sure the space it is in will vent properly. And even if we are not going for extra capacity usually the fancier smart chargers generate more heat. So you will need to plan for that.

|

|

|

03-09-2022, 05:59 PM

03-09-2022, 05:59 PM

|

#31

|

|

Senior Member

Name: Shelby

Trailer: Casita SD

Tennessee

Posts: 1,109

|

Quote:

Originally Posted by computerspook

Weird. Don't know if he is confused or if he did not communicate well. There should be absolutely no problem with the output from a Lithium battery. The fact that you say that he mentioned the frig would indicate to me he is confused. A lithium should be putting out the same voltage and amps as a lead acid. So for using the power from one there really is no difference.

Now as mentioned here the charging is kind of a different thing. When it comes right down to it, a lead acid really can take whatever reasonable charge you send at it. If the charge voltage is within range it will protect itself and make sure it is not charge too fast. And again within reason it will not over charge. Now most systems think 14 - 14.4 volts is a good charge voltage is a good charge voltage. And that will shorten the life of the battery a bit. The ideal is 13.8 volts. But all of this will not cause major problems as long as it is reasonable. BUT lithium are different.

It is possible to both charge a lithium too fast and too much. Especially too fast. A lead acid really only has a charge voltage spec. And as long as you are within spec you are good regardless of the status of the battery. Now a lead acid will give out voltage and over time that will drop as it becomes discharged. A lithium will do the same thing with a different discharge curve, but really the same thing. Both can end up will below the desired 12 volts. But then when it comes to charging things become vastly different.

When you are ready to charge your lead acid battery you just hook it up to voltage within the charge spec. Even it it is say at 8 volts it will charge a bit faster than at say 11.5 volts. As the battery charges; some, hopefully most, of the energy is put into the battery as a charge that can then be drawn out. But some turned into heat by what is called internal resistance. With a lead acid battery this internal resistance and other factors make sure that your battery doesn't get damages and nothing bad happens because of the heat. Now if there is an internal short the battery can crack and lead acid. But that is about as bad as it gets. Some times in rare cases there can be a hydrogen explosion, but those even are close to impossible with a modern battery. That is why we use battery boxes by the way so a failure can be easy to deal with. BUT note I said lead acid. This is also true of most other types of batteries. But it is not true of a modern lithium (or phosphate) battery.

A lithium battery will accept a charge at a rate that heats it up and messes it up. A lithium battery will have both a charge voltage spec, BUT also a charge rate spec. Now with a lead accident you in a lot of cases don't really need a "charger". All you need is a supply of voltage what matches the spec. If the battery calls for say 13-14 volts then the power supply can put out 14 volts and the battery will take it in. IN most cases the power supply system such as a "battery charger" will quickly get to its maximum rate and drop the voltage, but that is to protect the wiring and the unit. It is not to do anything for the battery. In fact you probably have experienced this. If you have been running on battery and drain it and then hook up to shore power and let the converter run the camper and charge the battery you will notice that at the start the power to everything is a bit lacking. The lights will be a bit dim and the stove spark may not work. But then in a few minutes all is good and you wonder if you were experiencing this or not. What happened is that the battery was taking enough current from the converter that it dropped in voltage so that to much current for the wiring and for it would not be generated.

If you were to hook up a charger capable of say 200 amps dc of the proper voltage to the battery it would be perfectly fine. Its internal resistance will drop the amps to match the batteries ability to shed heat. Now there can be a problem if there is a short, but then all that happens is that the battery cracks and then stops taking any current. And when that happens the battery was already toast anyway. A healthy lead acid battery would be quite happy hooked up to this device. In fact we do that regularly. Remember those booster chargers that allow you to start a car with a dead battery without first charging it up. That is exactly how they work.

But as I said lithium is different. It is possible to charge a lithium to fast. And if you do you can get a much more "spectacular" result than with a lead acid failure. You can get a fire or even an explosion. But only if they are charged wrong. Do things right and you are good. You would not even need the battery box because the cracking and leaking because the battery went bad is not possible. But a healthy lithium can be charged to fast and go into failure. Now if you were to say hook that 200 a,p power supply up to about any lithium battery designed for 12 volt deep cycle use and you will get a very bad result. You probably would not want to be any where near it. There are even a couple of youtube videos by the "lets film stuff really blowing up or burning spectacularly" channels. But again that is if you are charging it improperly.

Remember that comment I made about the lithium (and phosphate) batteries having a charge rate spec. That is the issue. It is possible to charge a lithium battery to fast and put it in failure. Even if it is not spectacular it will be dead and they are expensive. And most of their warranties don't cover this. So dropping a "12 volt" lithium battery into a camper and using it to power the camper should be fine. But if you then charged it the same way that a lead acid battery is charged you will be very unhappy. And you can charge them one of three ways. This is kind of hinted at above, but lets talk about this directly. First obviously you can just hook a battery charger up across it. That is the most obvious one. Everyone can probably understand this. The second way it that you can hook up shore power. Normally the way the converter that is the 12 volt part of shore power is wired is that the battery is just in parallel with the main. That is why when you first plug it in the voltage drops for the camper and then comes back up as the battery is charged. Then the third way is that the TV can be hooked up and probably the engine running a the alternator running and producing power. Again this is normally hooked up in parallel with the camper wiring and that battery (and the converter). The voltage will drop while the battery is charging. Now most of the time the wiring going to the rv7 connector and the distance will produce enough drop not to allow the battery to be over charged. But you would never want to count on this. In each case basically the voltage produced is either like 13-14 volts or the maximum the source can put out without regards to the needs and requirements of the battery. That as we have said is fine for a lead acid battery for which this system is designed. But it would be disastrous for a lithium or similar battery.

The prevention of a over charge is where a lithium battery charger comes in. These are in a way true battery chargers and not just a dumb power supply used to charge the battery like we see with a lead acid battery. They are actually "smart" mostly they actually have a small computer of some kind in them. That small computer knows all about lithium and other batteries. And it prevents over charging. They are also smart enough to detect a damaged battery and will not allow any charging, so they will not allow a damaged battery to do damage. They will drop the voltage in order to prevent the battery from getting charged to fast and failing. Now strange as this sounds they will frequently at the start of the charge limit the voltage to well below the level of being charged. If you have discharged a lithium battery to say 8 volts (you should not really do ths, but it happens) then the charger will prevent more than say 10.5 volts from being sent to the battery and then up that voltage to maintain the rate till it is fully charged. And as I said if the battery is bad the charger will goto 0 volts and put out an indicator of why. By the way some bad lead acid batteries can be resurrected by hooking them up to a lithium charger. Actually a lithium charger will handle a properly sized lead acid battery with no problems. So if you are not already trying to make the change, but are thinking of in the future and you are replacing your converter (more on those below) you can actually get a lithium one and use it on your lead acid until you make the switch.

Now how to get a lithium charger in this case is the question. Now for a battery charger that is easy. Get a battery charger which is rated for lithium. The only catch here is that current rate spec that does not exist for lead acid batteries. And that rate is important and is different for different batteries. So you will either need to get a charger that is rated for the current spec of the battery or which can be adjusted for that rate. And then remember to adjust it. That is the easy side. The RV converter is another side.

Now back to the original question. The author specified that the camper had no converter. I would certainly question that and double check it. But I guess that is possible. Might be a great time to add one as you can add one that supports lithium batteries as your charger. Now a seperate question is what happens to power from the TV is it routed into the camper wiring or is it disconnected? Important questions. And that will change how you handle this. I am going to assume that you have both as that way I can explain the process with all of them if you don't have one you will just skip the steps involving them.

The first thing to do is to get a converter that will support your lithium battery. You will need one with the smart charging functionality of a lithium battery charger. Now as I covered above most converters are kind of dumb and are simply hooked up to the battery, the HV and camper DC wiring in parallel. When the converter has power it just puts out power to its maximum rating. As a 35 amp convert will put out 13.8-14 volts up to the limit of its 35 amp capacity. Then it will drop the voltage as needed to not put out any more than that. But remember that will like pretty much insure you lithium battery is killed. The first thing you will notice about the new converter (other than it is much more expensive ;-) Is that it has multiple places to attach wiring. A normal converter generally has a single set of connection points. Generally a red (hot) and black (ground). Then some times an actual ground connection. It is pretty easy to wire this in. Just connect it up to the camper wiring and it is connected to everything it needs to be connected to. And that almost always is the way that camper wiring comes today. So only that style of converter will be "plug and play" that is turn off the power, disconnect the wires. Remove the old unit and install the new one. Then hook up the same wires to the same type of places and turn on the power. Sorry it will not be that simple to do the news setup.

There will be several steps and some rewiring needed to install the new lithium supporting converter. Always good to take a bunch of pictures of what you have now and label it. But now the first steps will be the same. Pull all of the power. Remember to disconnect the battery. ;-) Remove the wiring for the old unit and uninstall it. Now the new steps. First figure out exactly where to install the new unit. Probably where the old one is but in some cases you will need to move it, or more likely reorient it. Now set the current levels for the charge. After all that is why we are here right. Now some of these new fanciest converters will actually allow you to hook up and charge two separate lithium batteries. Of course that is more expensive. In some cases you can hook up batteries in parallel and up the charge rate. Get lots of advice from an expert before doing this. Now install the unit.

Time for the wiring. Now you will need to get power to it, and this generally will be the exact same way as the old one. And then you will hook up the trailer wiring to the place on the converter that is labeled for that. Now the new part. First the battery. Remember that the old battery is just hooked up in parallel with the trailer wiring in some manner. Some times this is at the converter. A few converters for lead acid have a separate battery connection and wiring to the battery box. That will almost never be how they leave the factory. But mine actually has that. In that case hook that up to the battery connection. But usually you will have to run new wiring for this. I use heavy duty drop cord wiring for this. Now some times you can buy this cheapest without ends as a place like Lowes. But generally it is cheaper to just buy a drop cord. And remember you will need to pieces here. But one way or other you will need to wire the battery box separately to the converter on the labeled ports.

Now we have that Tow Vehicle (TV). It also is most likely wired into the existing system in parallel with the camper wiring. In most cases the converter is at the back or middle of the camper and the TV therefore its wiring at the front. So usually the connection for the TV is wired into the camper wiring at the front of the camper. So you will need to find this point. Then you need to disconnect it and run the wiring for the TV power to the converter. This is where an expert may be needed. Remember the ground line for the RV 7 not only is ground for the supplied power, it also is the ground for the signal and tail lights. So you will have to plan on exactly how the ground is handled. And part of that is making sure that any route to the lighting is able to handle that current and also the current of the inside DC wiring. But regardless the RV hot needs to be connected to the right place on the new converter.

Now in a few cases there are actually also boxes which go between the camper wiring and the battery that takes care of all of this. But for the pricing if you can update the wiring to allow for a modern converter that will work better.

Now one other warning. Mostly when we replace the converter we also up its capacity. Going say form a 20 amp to a 40 amp. There are a lot of wiring issues on this other than the battery change, but mostly we want to do this. But that then ups the amount of heat the converter generates. So we need to make sure the space it is in will vent properly. And even if we are not going for extra capacity usually the fancier smart chargers generate more heat. So you will need to plan for that. |

Now, that's a post!

|

|

|

03-09-2022, 10:05 PM

03-09-2022, 10:05 PM

|

#32

|

|

Senior Member

Name: Ray

Trailer: scamp

Indiana

Posts: 849

|

Quote:

Originally Posted by ShelbyM

Now, that's a post!  |

Thanks. Hopefully it helps someone.

|

|

|

03-10-2022, 10:10 PM

03-10-2022, 10:10 PM

|

#33

|

|

Senior Member

Name: Charles

Trailer: Bigfoot

Georgia

Posts: 392

|

Virtually all absorption fridges have a controller circuit that is 12v DC, no matter whether it is being operated on propane, 120v AC or (if a three way) on 12v DC for the heat element (which is about useless).

The concern the tech expressed to EllPea is that the voltage of the lithium batteries is going to be higher than the fridge is used to or probably was designed to run on. The fridge circuits are probably not expecting to see over 14v if that much, and with the potential of up to 14.6 or greater, the controller could be fried from over voltage.

Over on the Escape forum this has been discussed with reference mostly to the Maxxfans, but also to other equipment such as fridges and furnaces.

You might read this thread, https://www.escapeforum.org/forums/f...ues-22334.html

and also read the threads that tdf-texas links to in his posts, as he gives you information on the minature voltage regulators he installed on his fan, fridge, etc, to prevent the control circuits from being destroyed.

Charles

__________________

'03 Ram 2500 CTD, 5.9HO PacBrake six speed std cab long bed Leer top and 2008 Bigfoot 25B21RB.. Previously, 2008 Thor Freedom Spirit 180, SOLD! 2007 Winnebago View 23H Motorhome, SOLD!

|

|

|

03-10-2022, 10:30 PM

03-10-2022, 10:30 PM

|

#34

|

|

Senior Member

Name: Charles

Trailer: Bigfoot

Georgia

Posts: 392

|

Quote:

Originally Posted by Raspy

Rodre,

The video you linked is not the original Victron video that made the burnout claim, and it seems to have been taken down, but your video came to the same conclusion. That is, at 1500 RPM. And they stated that 1500 RPM was above engine idling speed. That is true for the engine, but not the alternator. In vehicles, alternators are belted to the crankshaft with a three or four to one ratio. Engines typically idle at about 750-800 RPM. So, the minimum speed a typical alternator would be running at would be approximately 2,250 RPM - 3,200 RPM. And alternators are typically, or always, mounted behind the engine fan. The test shown had no extra fan blowing on the alternator. These and other problems with the video do not represent what happens in the real world with charging systems and should not be used to demonstrate that alternators will burn out if used to charge lithium batteries. There's more to the story, such as alternator rated output, wire size and wire length.

|

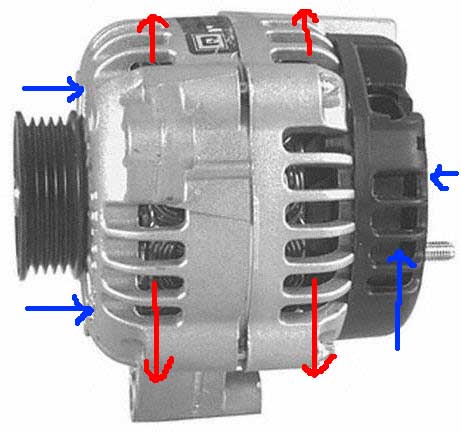

Virtually all alternators nowdays have INTERNAL cooling fans mounted in the FRONT of the alternator inside the housing. They draw air thru the rear, and forward through the components and eject the air out the front of the alternator around the outer edge of it. Engine cooling fan air blowing on the alternator is actually more of a detriment than a help, but largely a wash as far as cooling effectivity. Think of the many automobile engines that have sideways mounted engines with electric fans that don't always run.

An ideal installation is to have large (4 gauge or so) positive and negative cables running to the rear of the vehicle, to a B2B charger that supplies the RV lithium batteries. and the input of the 7 pin on the trailer side being disconnected. This allows the B2B to do all of the charging at an optimum voltage for the lithium batteries (which most modern computer controlled alternator systems will not reach) and also prevents draining of the tow vehicles batteries when shut off, as the B2B charger ceases to charge when input voltage drops below a certain point.

Modern computer controlled alternators charge heavily only for a few minutes to top the vehicle battery from the start up, and then drop the voltage back, as this becomes a fuel saving technique plus a battery saving technique. Notice how batteries in cars and trucks last so long now. Its not by accident, it is in part due to better batteries but also and I think largely due to the lower voltage not cooking the lead acid batteries. However this voltage is not high enough to top off most lithium batteries. It will charge them, but not give them a 100% charge.

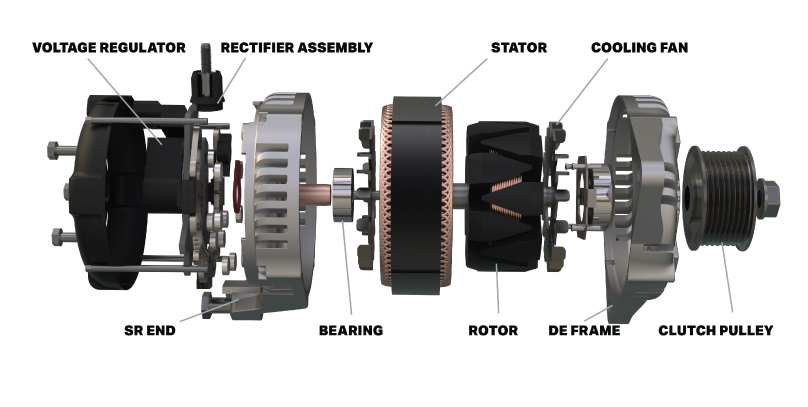

This alternator has dual cooling fans, both on the front and rear of the rotor, drawing air in both the front and rear and ejecting it out the sides.

Charles

__________________

'03 Ram 2500 CTD, 5.9HO PacBrake six speed std cab long bed Leer top and 2008 Bigfoot 25B21RB.. Previously, 2008 Thor Freedom Spirit 180, SOLD! 2007 Winnebago View 23H Motorhome, SOLD!

|

|

|

03-10-2022, 11:52 PM

03-10-2022, 11:52 PM

|

#35

|

|

Senior Member

Name: John

Trailer: Escape 21, behind an '02 F250 7.3 diesel tug

Mid Left Coast

Posts: 2,941

|

Lotta fiction on this thread, but I'm camping and on my phone.

My fridge hasn't minded the 14.6v output of my PD4655Li. Neither has my Maxxfan. If my batts (416AH 12V LiFePO4) are run down, the PD4655Li dumps 50A into them til they are 98% charged. I used a dc-dc converter to kick up the tow vehicle juice to 13.5-14.4v at 18A, my tow vehicle is fused at 40A.

|

|

|

03-11-2022, 12:03 AM

03-11-2022, 12:03 AM

|

#36

|

|

Senior Member

Name: John

Trailer: Roamer 1

Smith Valley, Nevada

Posts: 2,892

|

Quote:

Originally Posted by CharlesinGA

An ideal installation is to have large (4 gauge or so) positive and negative cables running to the rear of the vehicle, to a B2B charger that supplies the RV lithium batteries. and the input of the 7 pin on the trailer side being disconnected. This allows the B2B to do all of the charging at an optimum voltage for the lithium batteries (which most modern computer controlled alternator systems will not reach) and also prevents draining of the tow vehicles batteries when shut off, as the B2B charger ceases to charge when input voltage drops below a certain point.

Modern computer controlled alternators charge heavily only for a few minutes to top the vehicle battery from the start up, and then drop the voltage back, as this becomes a fuel saving technique plus a battery saving technique. Notice how batteries in cars and trucks last so long now. Its not by accident, it is in part due to better batteries but also and I think largely due to the lower voltage not cooking the lead acid batteries. However this voltage is not high enough to top off most lithium batteries. It will charge them, but not give them a 100% charge.

Charles |

Your first paragraph is exactly what I have been advocating for a long time. And exactly what I have done. A dc-dc charger to charge the lithium trailer battery, supplied by a separate set of high amp wires from the truck's starting battery. This is where the Anderson plug comes in, as the connection between the truck and the trailer.

"Smart" alternators won't properly charge lithium batteries, but they are great for lead acid batteries in the tow vehicle.

My main point about the alternator in the video was that it was undersized, run too slow to cool properly, said to be running at engine speed when it wasn't, had no additional cooling from any outside source, had large and short conductors to eliminate line losses and had a very large load. Everything was maximized to work against the alternator, and then the results were exploited to make a sales point that alternators would burn out if used to charge lithium batteries. That narrative is now preached by so many who want to sell something, when it might only be true under very specific conditions that have nothing to do with real world charging. It's dishonest. But it is true that conventional alternator programming in vehicles is not well suited to charging lithium batteries. This is because the charging voltage can be too high, because the absorption phase is much shorter on lithiums, because the lithiums need no float charge unless they are under load, and because the voltage difference from lead acid can mean that the lead acid batteries can become a load on the lithiums if not disconnected from each other.

A dc-dc charger is needed when charging lithiums from a conventional tow vehicle charging system. But a dc-dc charger is optional if charging lead acid trailer batteries from that same vehicle.

Part of that decision centers on the size of the conductors. Will someone be trying to charge with the seven pin wiring, or with large conductors installed just for that purpose. I had a set of #6 wires from the tow battery to my AGMs in my Black Series for nearly two years and charged every time I towed. It worked very well. On my Xplore X22, and my new truck, I have a set of #4 wires to the rear of the truck and #6 wires in the trailer, to charge the Lithium bank. Under some circumstances, I would charge directly from the truck before I got my dc-dc charger installed, and it worked OK. I had to be careful with it, but it worked. Now, it is all automatic with an Orion 30 amp dc-dc charger. The only problem is the incompatibility with the solar during the day.

My F250 has a smart charging system. it starts out at over 14.6 volts and then after a short period, drops to less than 14.5. After a long period is settles at about 14 or slightly less. The lithiums do not want voltage of 14.6 or higher, and prefer 14.4. So, before the dc-dc charger, my strategy was to wait until the voltage dropped to under 14.6 and then plug in the trailer. I was able to charge this way for hours while pumping at least 20 amps of current into the lithiums, and not once did I burn out my alternator! I have a dc volt meter in the truck and can watch the voltage all the time. I've never seen less than 14 while charging the lithiums during long drives. And since I never pulled them all the way up to the absorption phase, I never had to worry about overcharging them. My lithium bank is 480 AH and I didn't charge them while driving unless they were pretty low. And the only reason they ever get low is because the weather is cloudy and cold. In that case I'm using a lot of power for the furnace blower, lighting, electric coffee maker, charging equipment, some microwave, and the compressor fridge. My solar is a 460 watt system that keeps up fine in clear, warm weather. I very seldom plug the trailer into shore power. Just once while on a trip in bad weather for a week, when I decided to use shore power instead of plugging into the Anderson plug on the truck, and recently at home because it has been very cold, the heater and compressor fridge are on and the trailer is parked in the carport, with no sun. Under normal conditions, no shore power is needed and we camp off grid all the time. It's a great thing to never be looking for campsites with power.

__________________

I only exaggerate enough to compensate for being taken with a grain of salt.

|

|

|

03-11-2022, 12:47 AM

03-11-2022, 12:47 AM

|

#37

|

|

Senior Member

Name: John

Trailer: Escape 21, behind an '02 F250 7.3 diesel tug

Mid Left Coast

Posts: 2,941

|

Lithium needs no absorption phase, just constant current up to 14.2 to 14.6 volts, then constant voltage of 14.2-14.6 volts until zero amps and some extra time to allow for BMS cell balancing, then optionally drop to 13.6v or so for float. "Absorption" is a strictly lead acid thing where after the constant voltage phase of around 13.8V the voltage is raised to 14.2 V or so for a time based on the total AH of the charge cycle before reverting to the float charge maintenance level of 13.6-13.8V

|

|

|

03-11-2022, 12:59 AM

03-11-2022, 12:59 AM

|

#38

|

|

Senior Member

Name: John

Trailer: Roamer 1

Smith Valley, Nevada

Posts: 2,892

|

Quote:

Originally Posted by CharlesinGA

The concern the tech expressed to EllPea is that the voltage of the lithium batteries is going to be higher than the fridge is used to or probably was designed to run on. The fridge circuits are probably not expecting to see over 14v if that much, and with the potential of up to 14.6 or greater, the controller could be fried from over voltage.

Charles

|

I don't agree with your analysis. Here's why:

Lead acid batteries routinely get charged to 14.5 volts or higher as part of their bulk or absorption phase charging, both with smart grid based chargers and with vehicle charging systems. I commonly see voltage above 14.6 in my truck, for instance. Conditioning voltage can reach 16 volts, but is probably not done in older systems without that option, however, many smart chargers, and some solar charge controllers do have a conditioning schedule for lead acid batteries. Charging voltages in cars, can be set as high as 15 volts continuous, but are still considered 12 volt systems. Trailer batteries are normally plugged into tow vehicles that are producing this voltage, and therefore, the equipment in the trailer is exposed to that voltage too.

Lithium batteries are limited to 14.6 volts, and prefer 14.4 volts. They should never see more than 14.6 and will never put that much into the system they are powering.

So, your position that 12 volt equipment will be damaged by high voltage from a lithium battery, designed to replace a 12 volt lead acid battery, seems impossible.

Voltages over 14 are a normal condition in any 12 volt system. "12 volts" is a category, not an an absolute value. In fact, lead acid batteries that are only producing 12 volts, are nearly dead and will be seriously damaged if left in that condition. The normal charging voltage for lead acid batteries is higher than the maximum allowed for lithiums. That's right, the normal for lead acid, is higher than the maximum for lithiums. If any high voltage was going to be a problem, it would be associated with the lead acid battery charging system. And since the trailer in question is an old one, it has been exposed to those lead acid voltages for all of its life. I do not see how lithium can be a high voltage problem. Please explain.

__________________

I only exaggerate enough to compensate for being taken with a grain of salt.

|

|

|

|

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Discussions

» Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

» Upcoming Events

» Upcoming Events |

No events scheduled in

the next 465 days.

|

|